Faculty members of the Centre for International Business Studies (CIBS) at the School of Business, Economics and Law, University of Gothenburg, together with faculty members of the Southwestern University of Finance and Economics (SWUFE), visit the Volvo Car Corporation Chengdu Plant (VCCD), China.

Text & Photo © CM Cordeiro, Sweden 2015

On 9 April 2015, faculty members of the Centre for International Business Studies (CIBS), at the School of Business, Economics and Law, University of Gothenburg, together with faculty members of the Southwestern University of Finance and Economics (SWUFE) had the opportunity to visit the Volvo Car Corporation Chengdu Plant (VCCD).

In the field of international business (IB) studies, there were many curiosities wrapped in uncertainties at the time of Geely Holding’s acquisition of Volvo Car Corporation (VCC) in 2010. Prominent interests pertained to the how VCC might be managed under Geely, of which came the answer that Volvo and Geely would be kept as separate entities [1,2].

Five years on from China’s acquisition of Swedish founded VCC, there was nowhere made clearer than from the visit to the Chengdu Plant how impressions of product branding go in both directions. As much as the European market wanted to keep Volvo a separate entity from Geely, due at the time of concern of safety and quality standards, the Chinese market had likewise concern, that Geely as a brand should not be conflated with VCC, due to the differing market segment base. In that sense, the first ‘big surprise’ came in the form of VCC having autonomous decision making capacity, from their Chinese ownership. This process was described as a paradigm shift in attitude within VCC, of how they were to function and develop in China, where they felt as if they had come home into themselves again, being able to create and innovate at will, towards profitability.

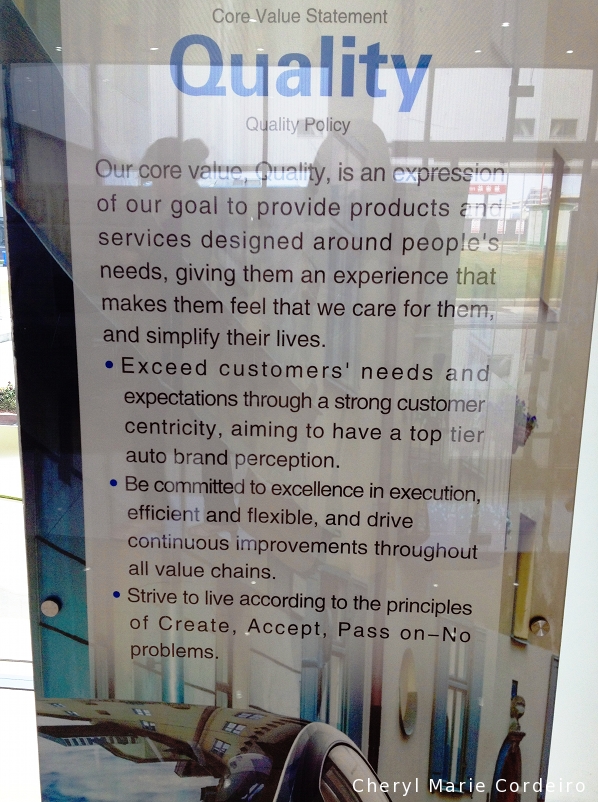

The current autonomy experienced by VCC also encouraged the business enterprise to continue its operations based on its founding core values of focusing on people, its customers, and the environment.

“So what is different in terms of managing people in Europe as compared to managing people in China?”

The general reply was that there was not much difference in the approach towards managing a workforce. Whether in Europe or in China, VCC puts the safety and interests of employees high on the priority list.

As a means of looking after its workforce, a stringent measure that VCC takes is keeping to the highest possible quality standards, from not overworking individuals to keeping individuals safe on the factory floors with its ‘Vision Management’ strategy that allows any manager a 360deg unobstructed view of the factory grounds in order to be at any point on the factory floor in under two minutes. This is achieved by glass walled offices, and having all equipment at no higher than 160cm from the ground. So far, the VCCD plant has registered fewer accidents in the last two and a half years with ca. 2,500 employees on the ground, as compared to its plants in Europe.

Keeping to stringent standards pertained also to team leadership training. Beginning with thirty team leaders in total, it was made sure that no more than twenty to twenty-five new individuals were recruited into the training programme. When the team leaders grew to ninety in numbers, eighty new team leaders in training were recruited. The strategy of not expanding too rapidly ensured that no one had more than one trainee to manage at a time, “because we don’t want to wake up one morning and have 2,000 employees who didn’t get the right training from the beginning.” What was important was for every employee to understand why they did what they were doing, and once that knowledge was internalized, it would be the employees themselves who would then teach newcomers about VCC’s quality standards and procedures.

People in China were treated no different than those in Europe. What a team leader on the front line of the manufacturing plant did in Europe for example, was also expected of a team leader in VCCD, China. A consequence of this expectation was that the team leader in China would be more involved in problem solving, compared to team leaders in neighbouring factory plants under different management.

What was illustrated at the VCCD plant was how there was a delicate balance between both product and employer branding. And it was this aspect of having an interesting job, coupled with the opportunity to develop as an individual in life, and being able to carve out a meaningful career that contributed to an overall lower turnover rate for VCCD, in a country known for its high annual labour turnover rate.

”It is not easy to find the right people with the right mindset for the job. So once you have found them, you have to take care of them so that they will want to stay, not because they have to stay.”

References

[1] Global Times China, 2014. Li Shufu: Geely and Volvo will join hands to develop electric cars, Global Times China. Internet resource at http://bit.ly/1FEwZeM. Retrieved 14 Apr. 2014.

[2] Anderson, G. E. 2012. Designated Drivers: How China Plans to Dominate the Global Auto Industry. John Wiley & Sons, Singapore, p. 147.

A signed car on display at the VCCD showroom.